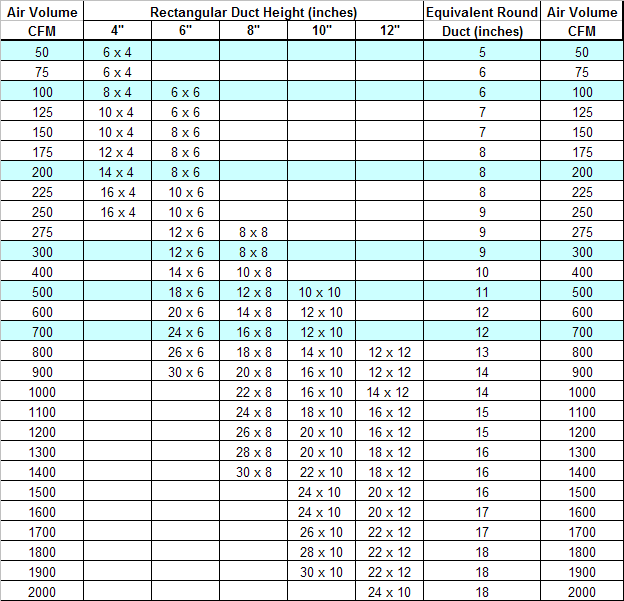

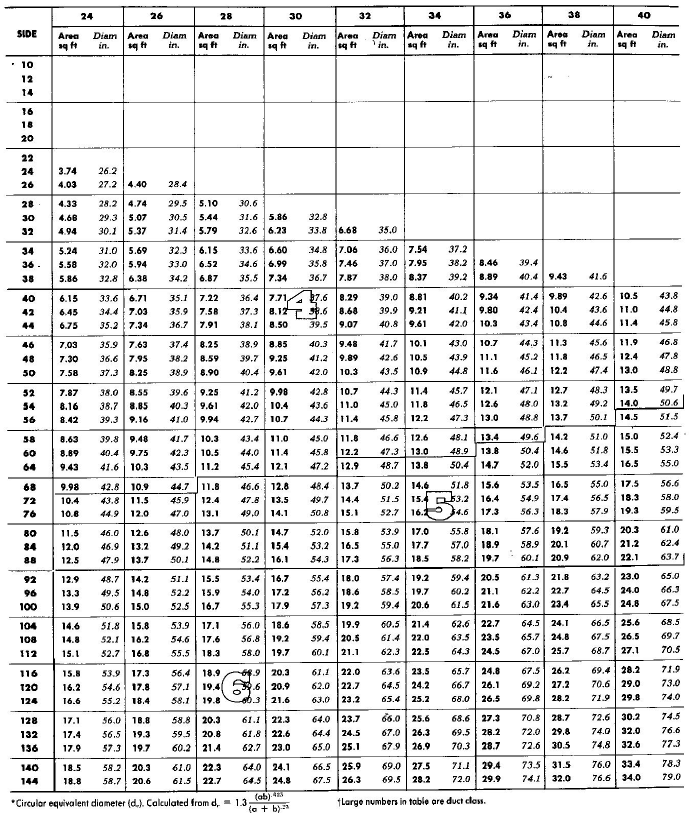

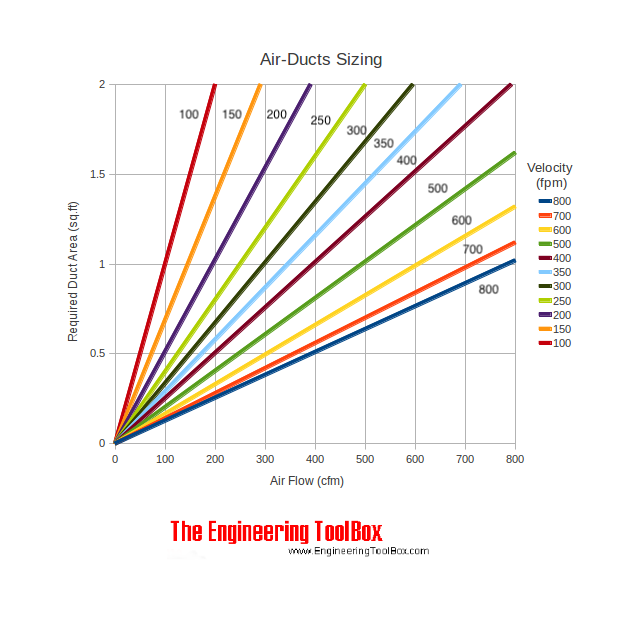

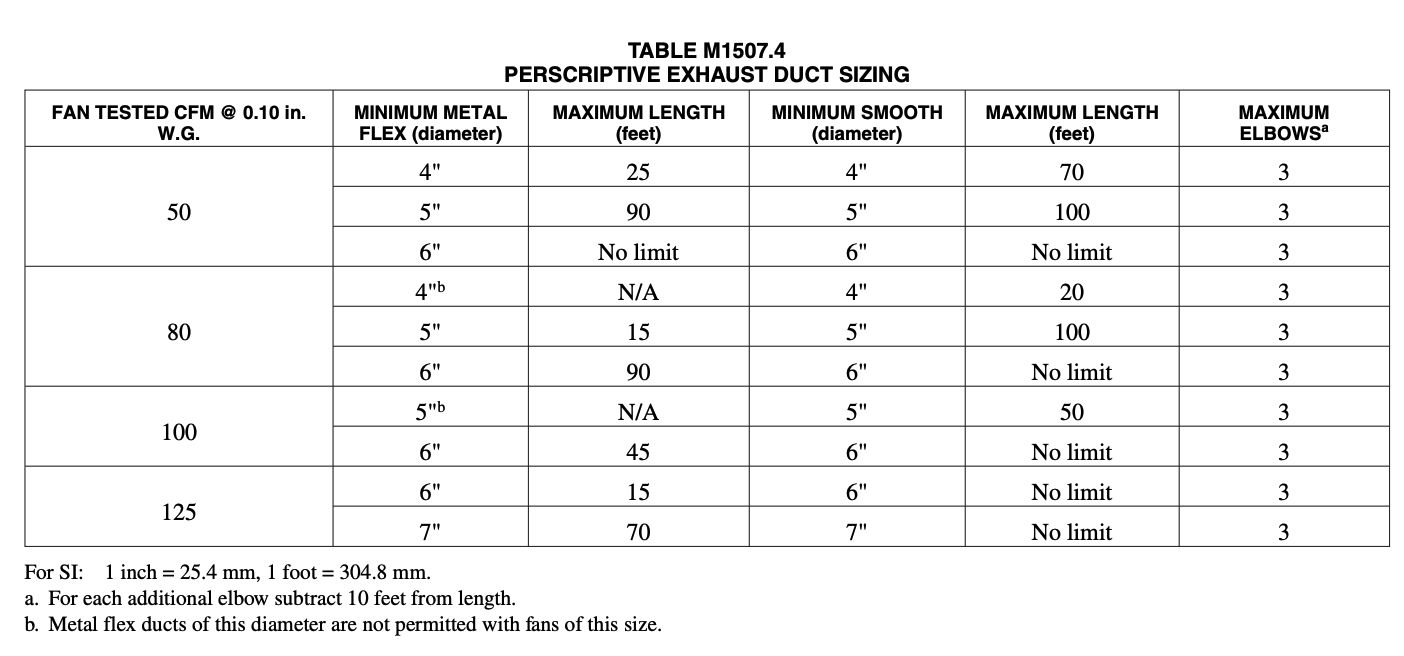

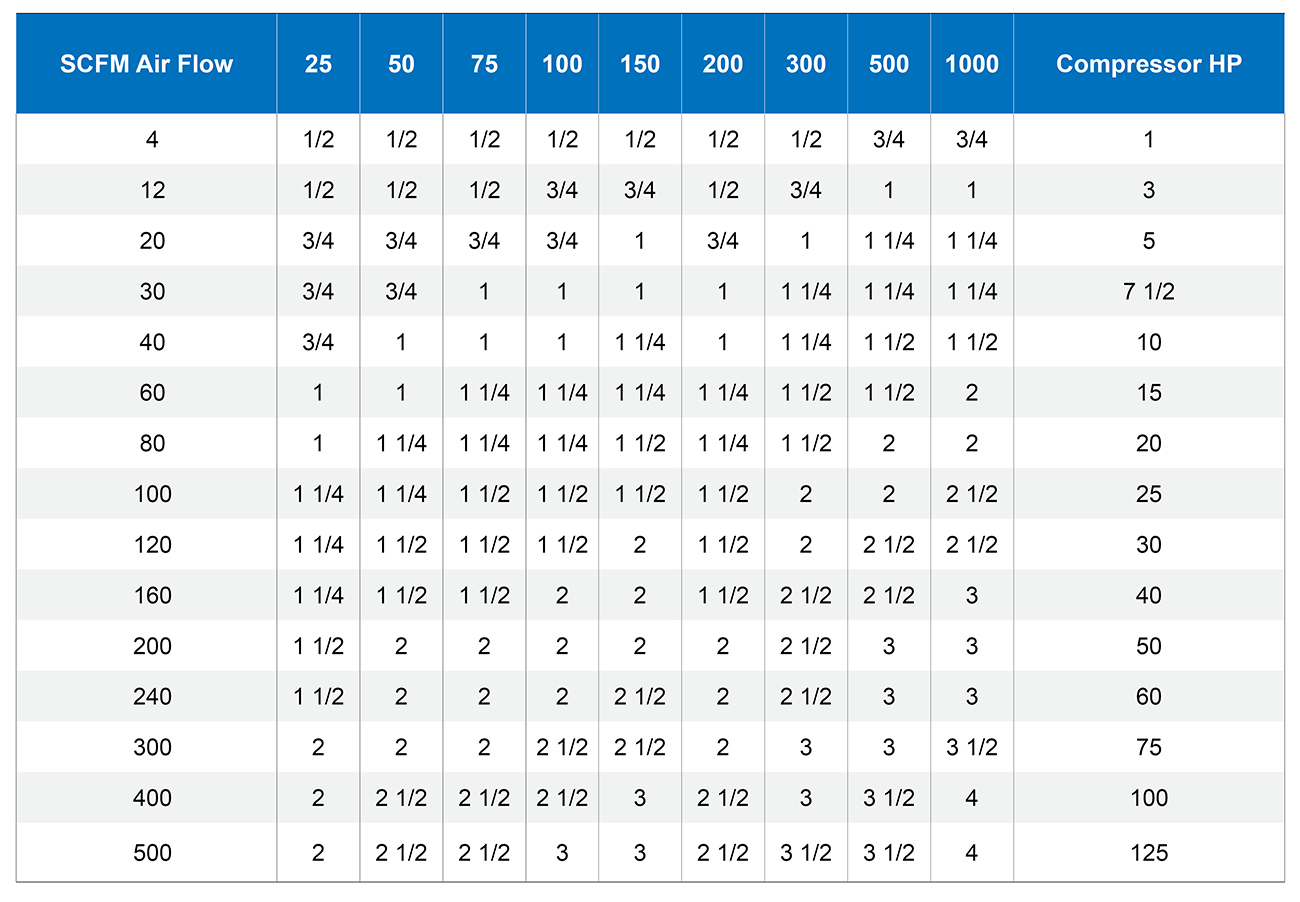

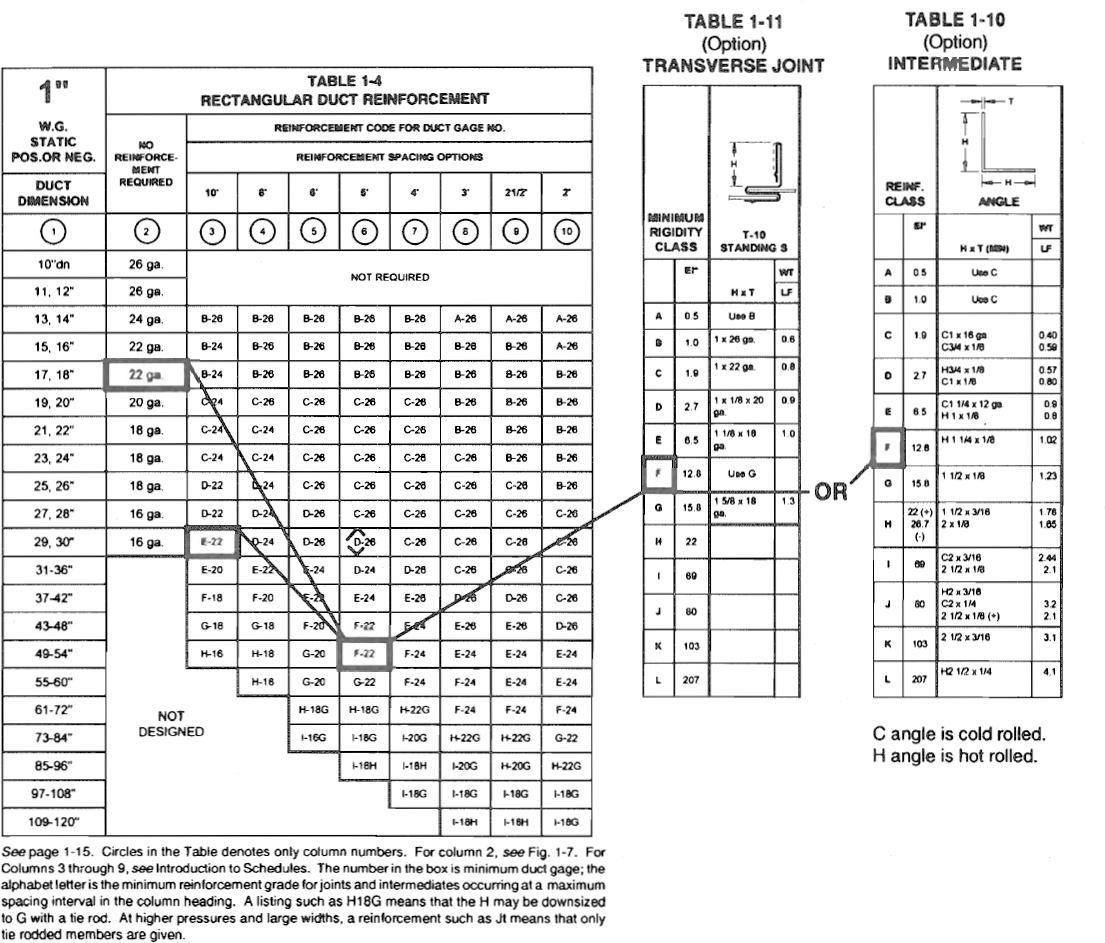

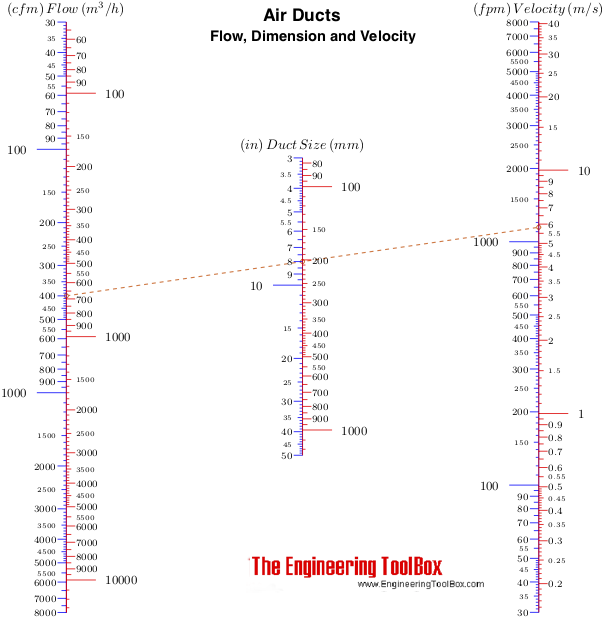

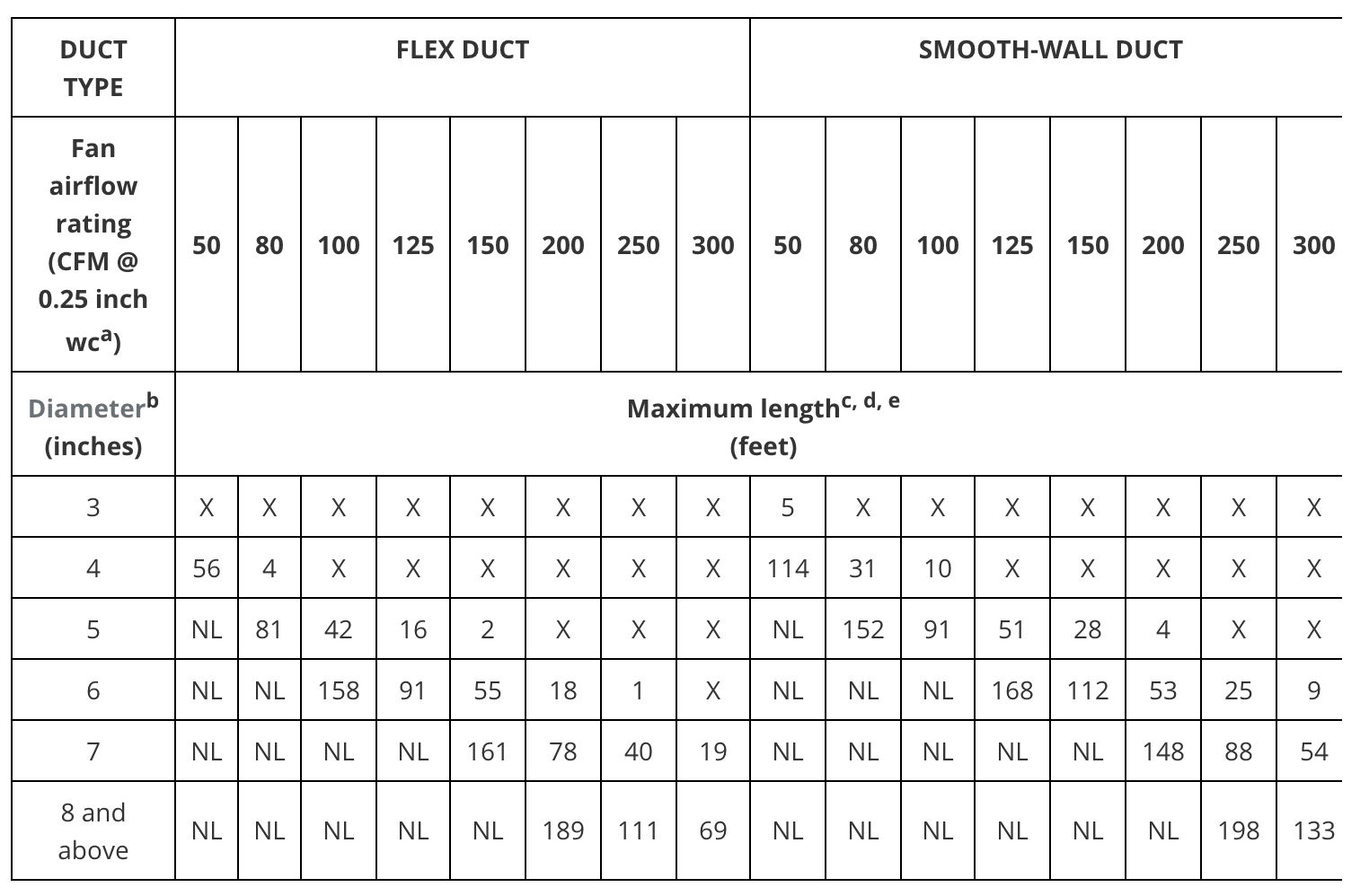

Duct Flow Chart

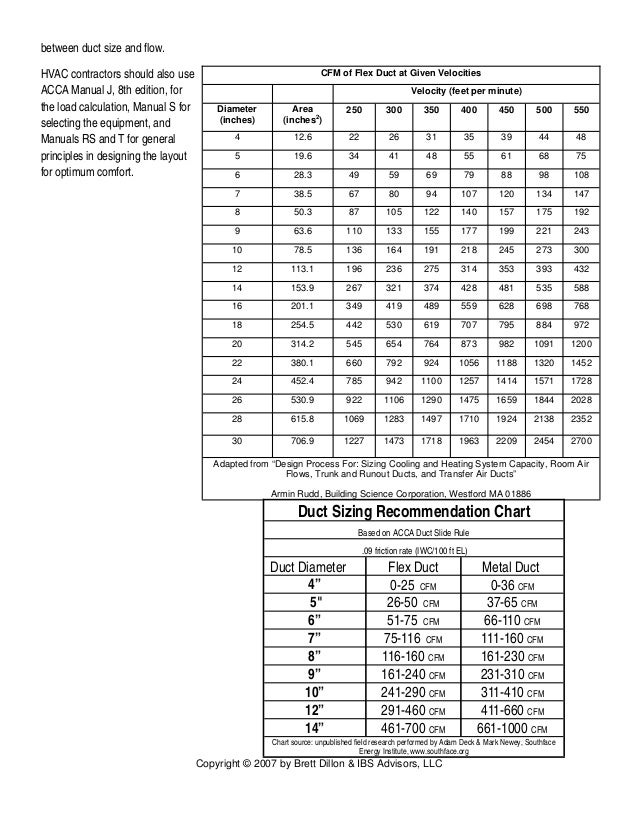

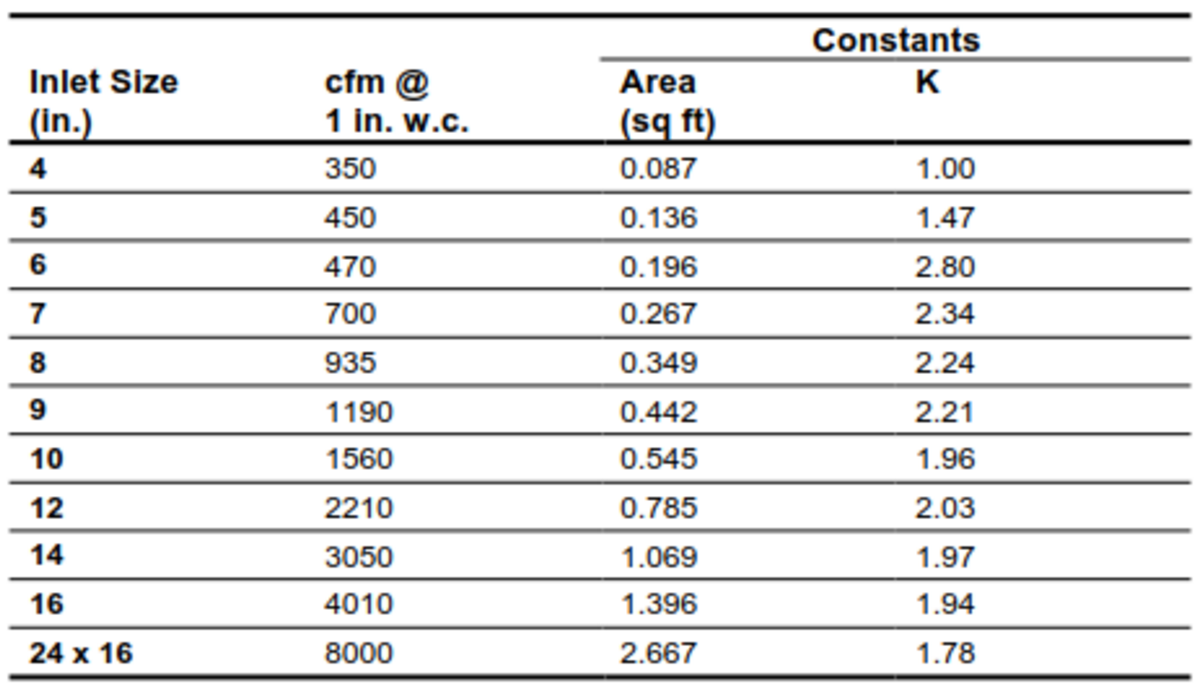

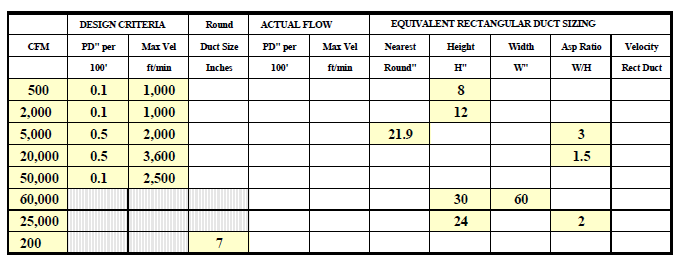

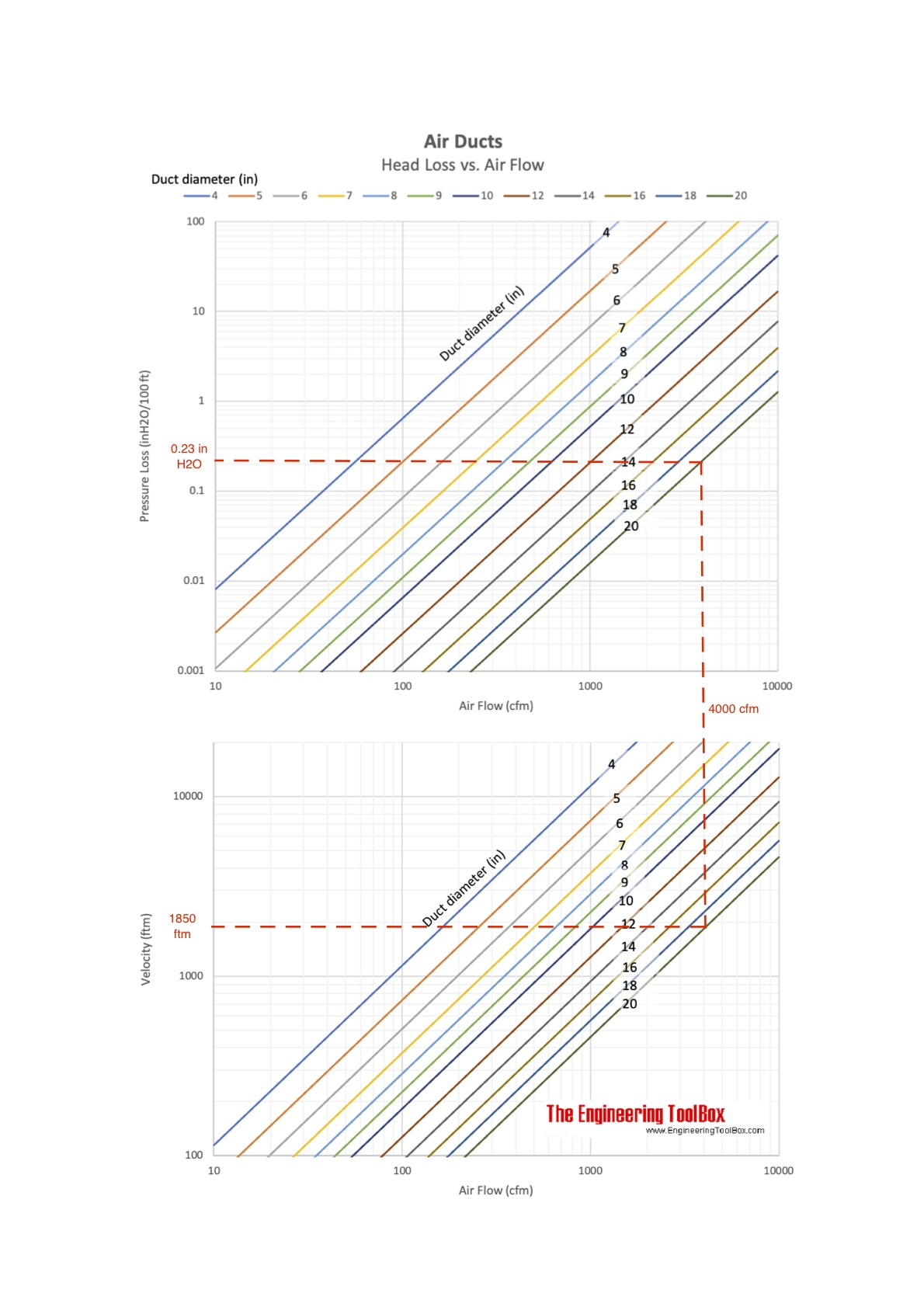

The duct size calculator is a quick reference tool for approximating duct sizes and equivalent sizes of sheet metal duct versus flexible duct.

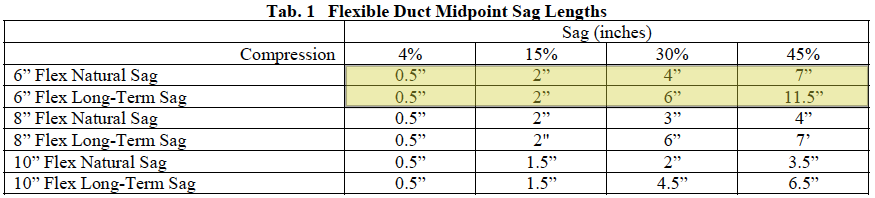

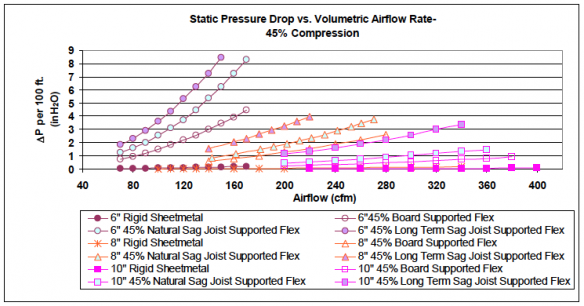

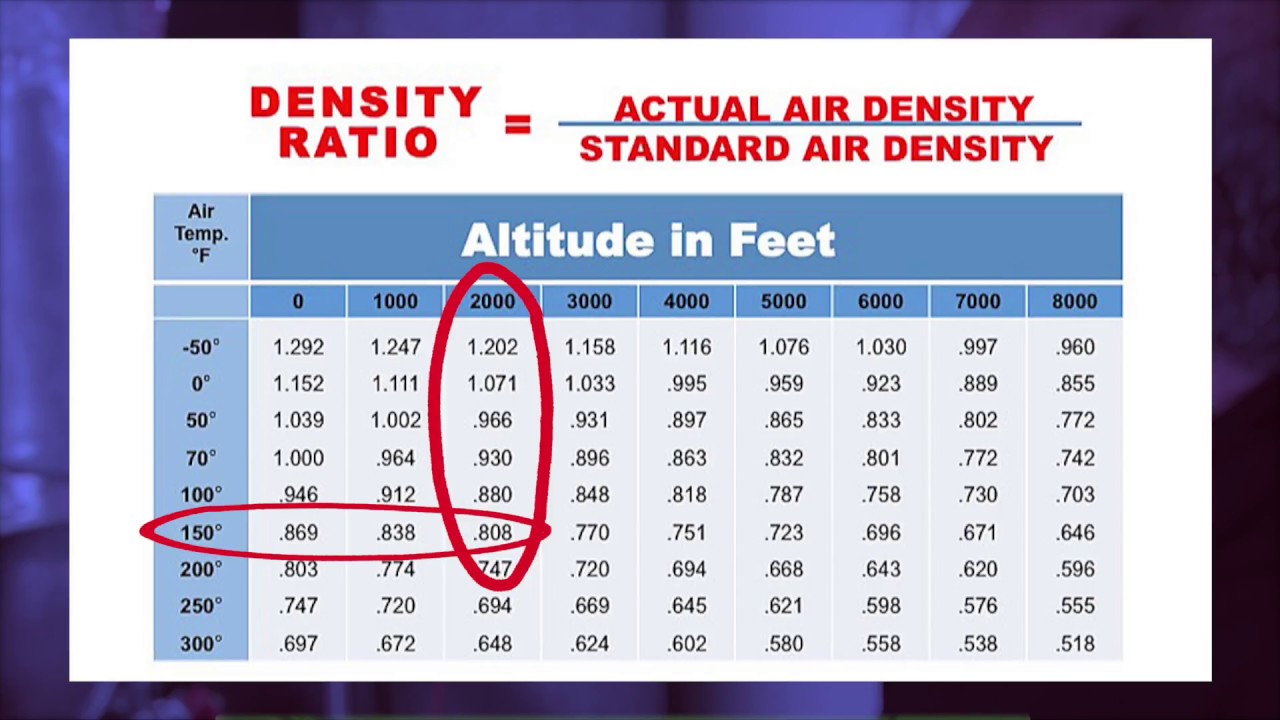

Duct flow chart. Weight of air photo by david hill. It includes sizing for metal ducts and for flexible duct when compressed at 4 15 and 30 straight line compression. Kb duct provides the widest range of ducting systems individual components and.

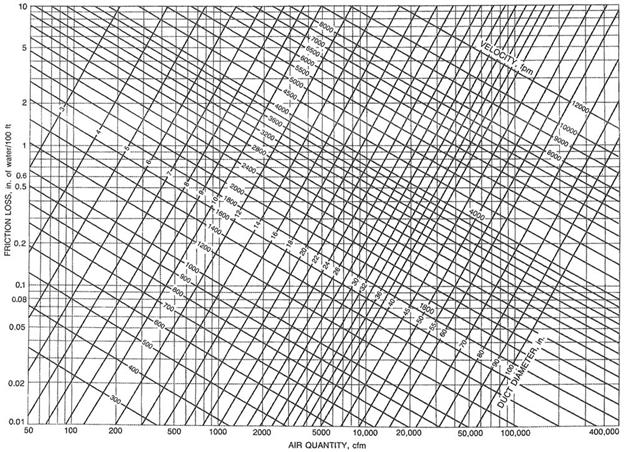

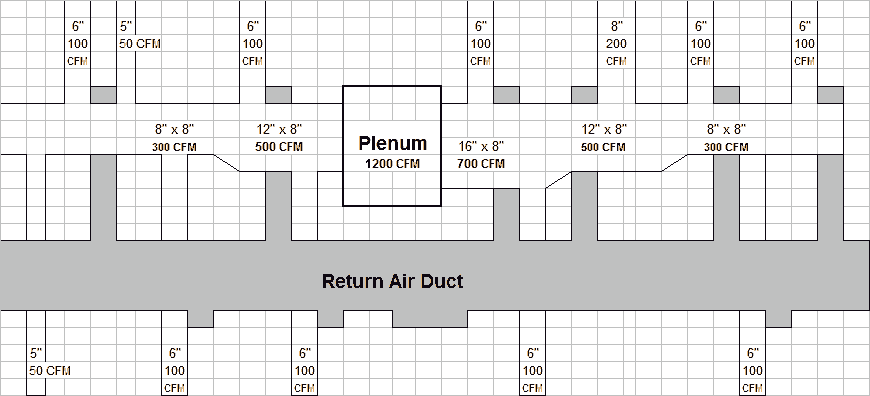

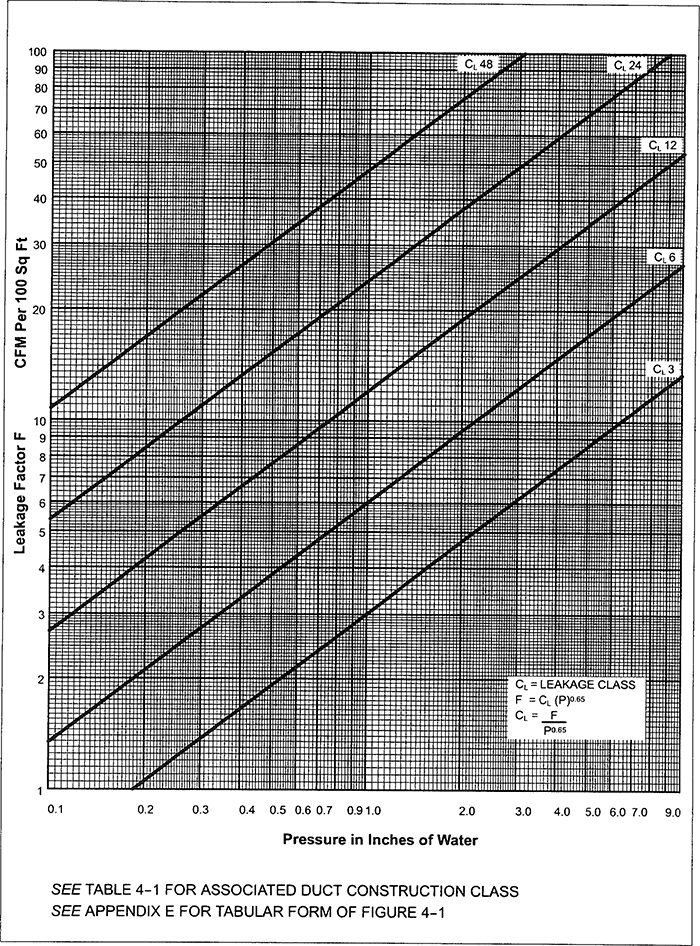

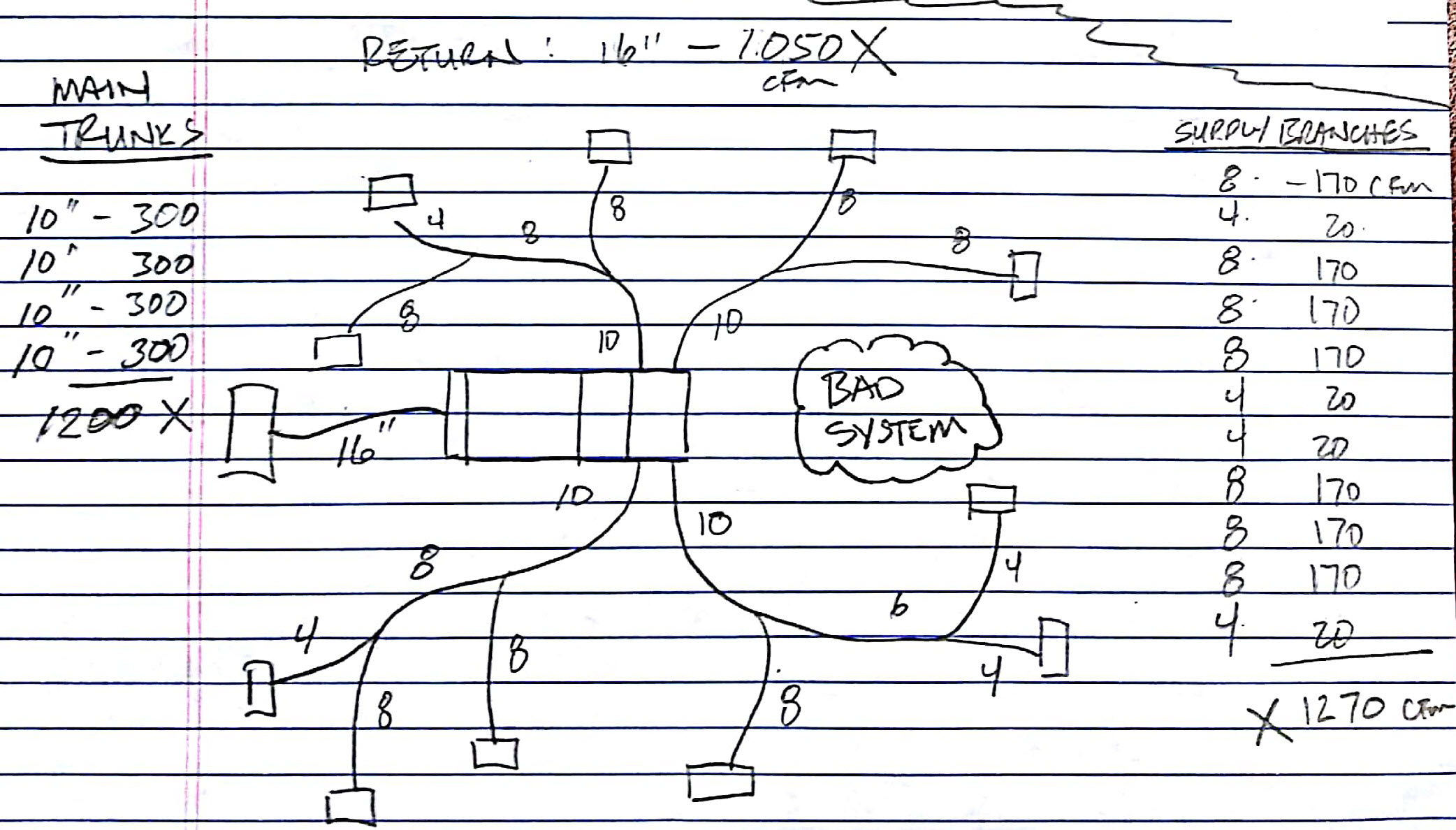

Never locate ducts at the end of the trunk line run. Typical environments that these flat nozzles are used for include house washing car washing truck washing parking garage cleaning awning cleaning water tower cleaning graffiti removal roof cleaning monument restoration and more. Friction loss flow charts.

Our kb duct brand is a leader in standard modular ducting systems clamp together and flanged individual components and application specific duct solutions for industrial dust fume mist and air handling systems kb duct began as a part of our kirk blum brand which has been in operation since 1907. The morgan lens allows for hands free irrigation so medical professionals can treat other injuries or transport the patient while irrigation is underway. The science of sag flex duct and air flow.

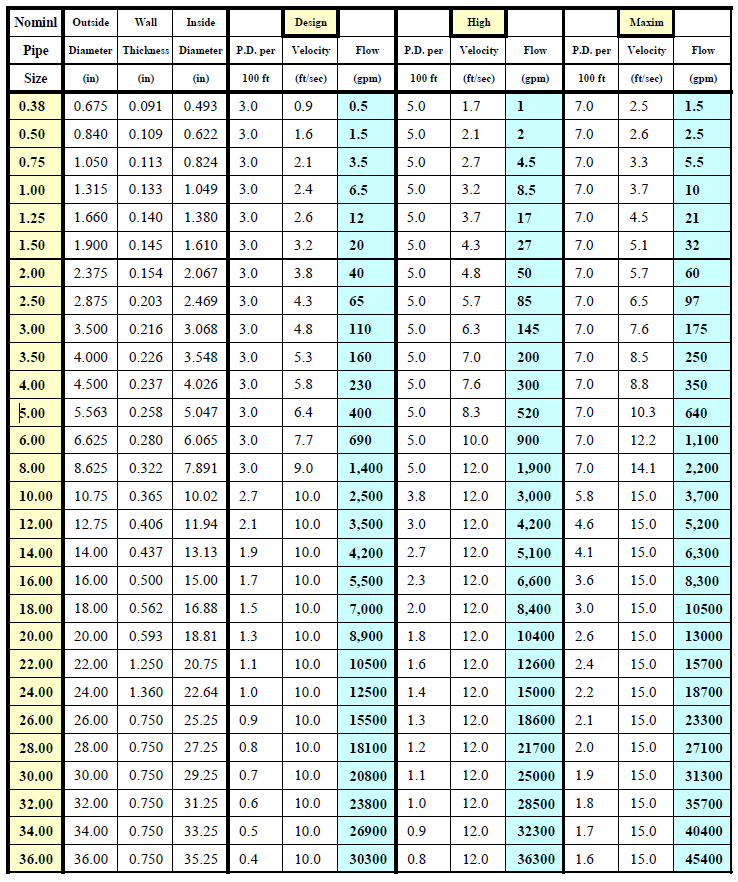

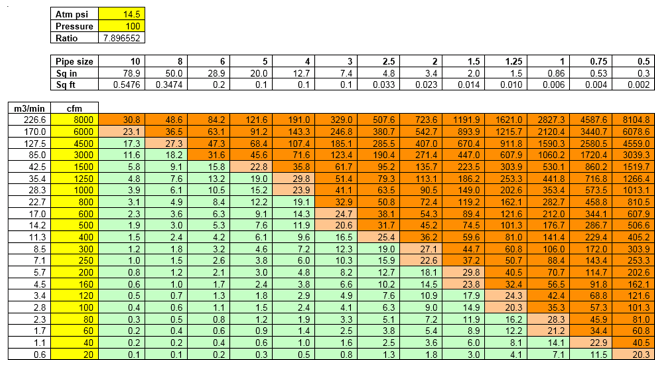

Using 1 pipe flowing at 5 gpm you would lose 1 72 feet of head pressure per hundred feet. Johns manville micro aire lp duct board is designed for use in manufactured and modular housing duct systems. Use insulated duct or duct board in unheated spaces.

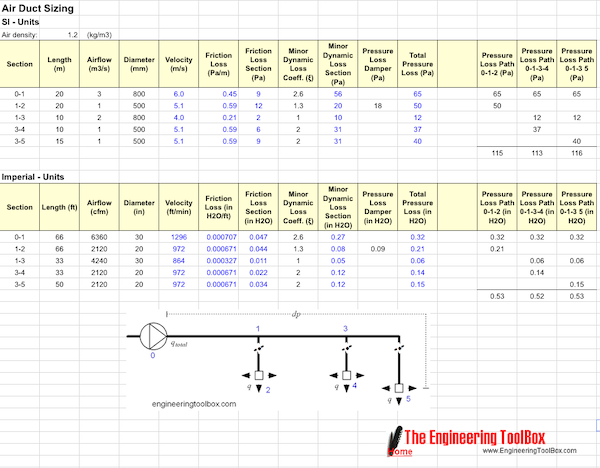

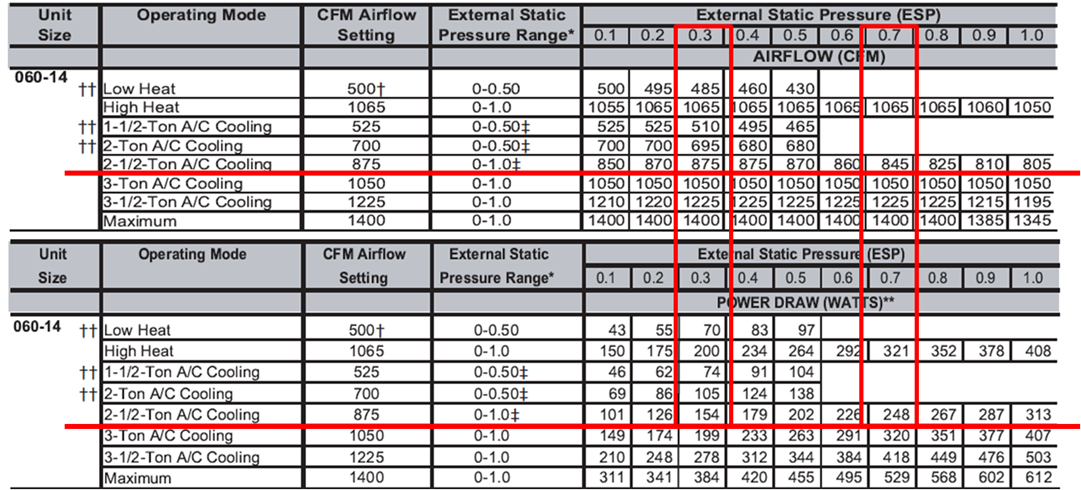

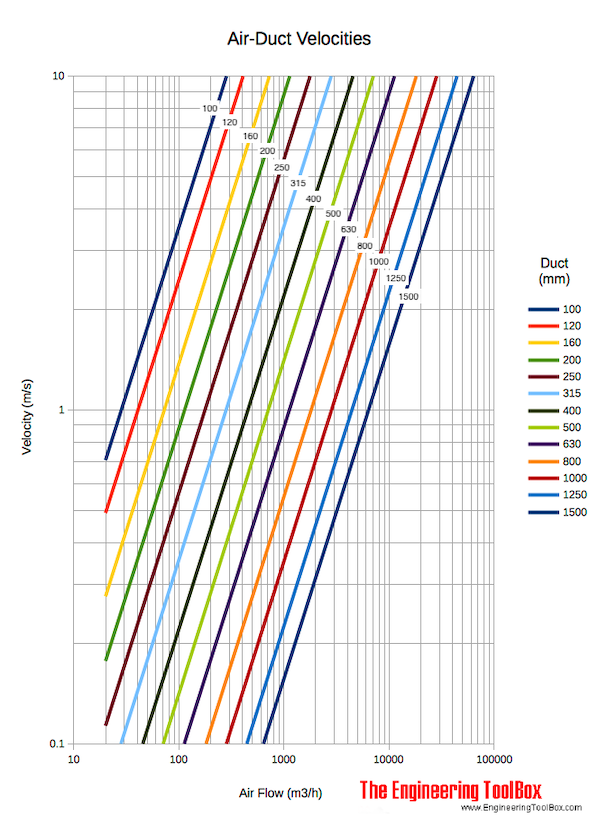

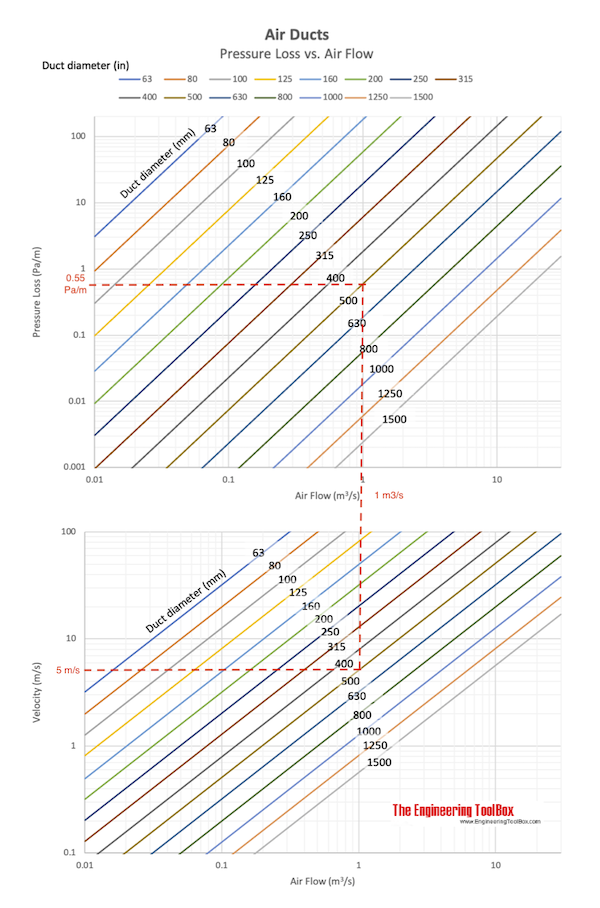

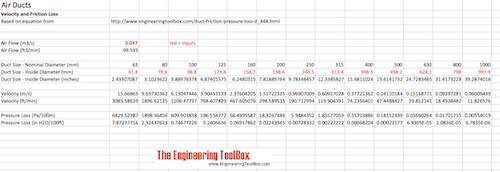

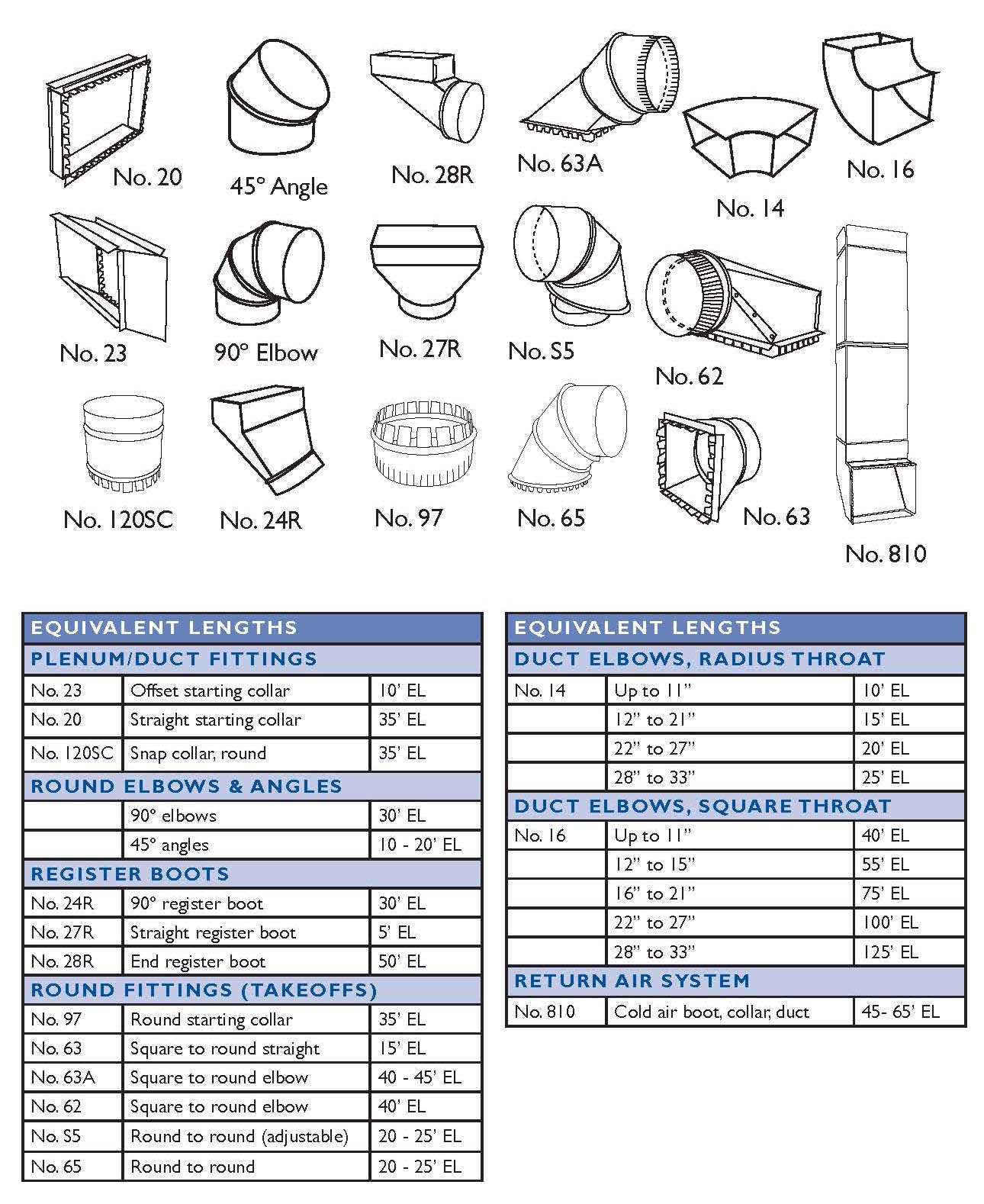

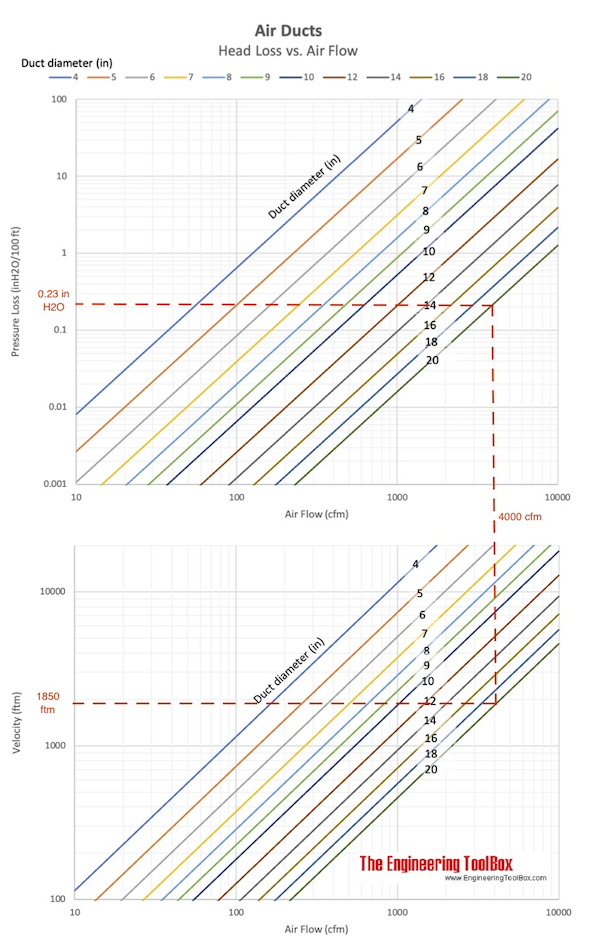

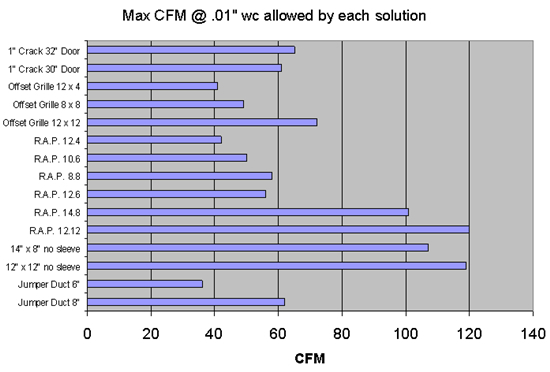

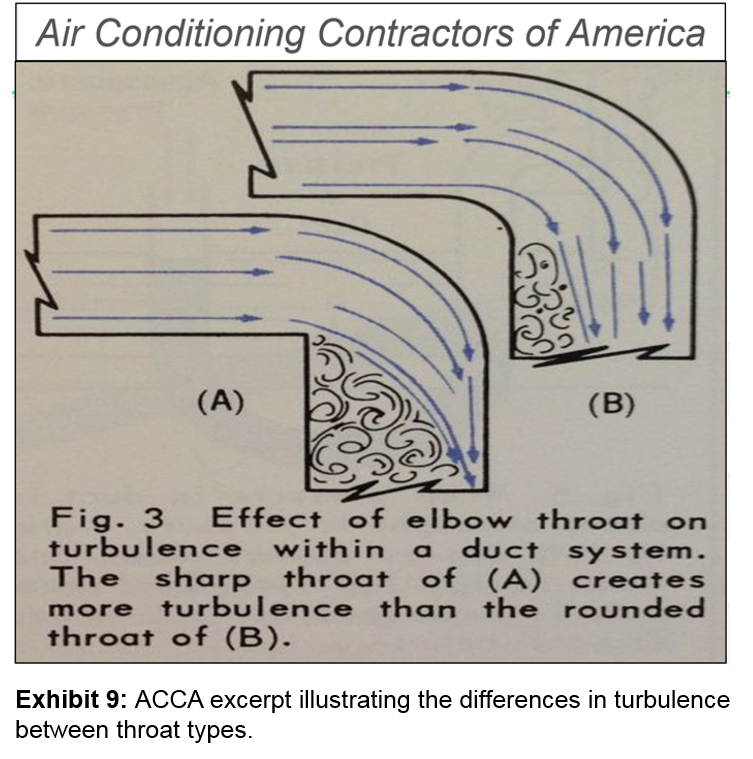

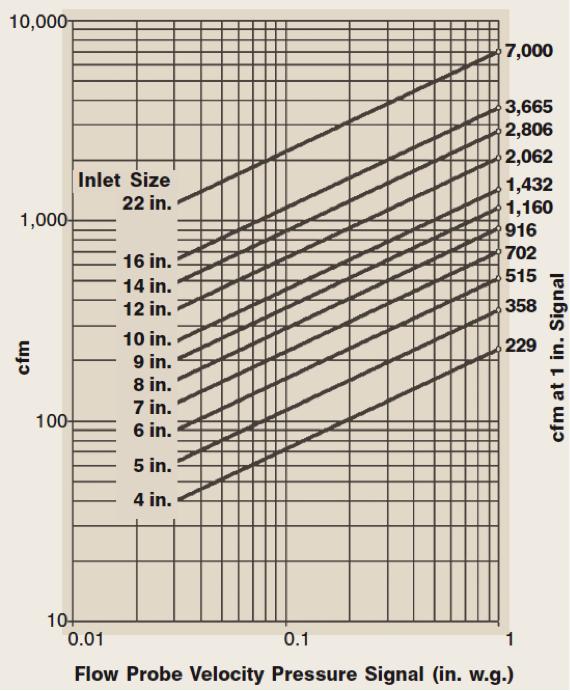

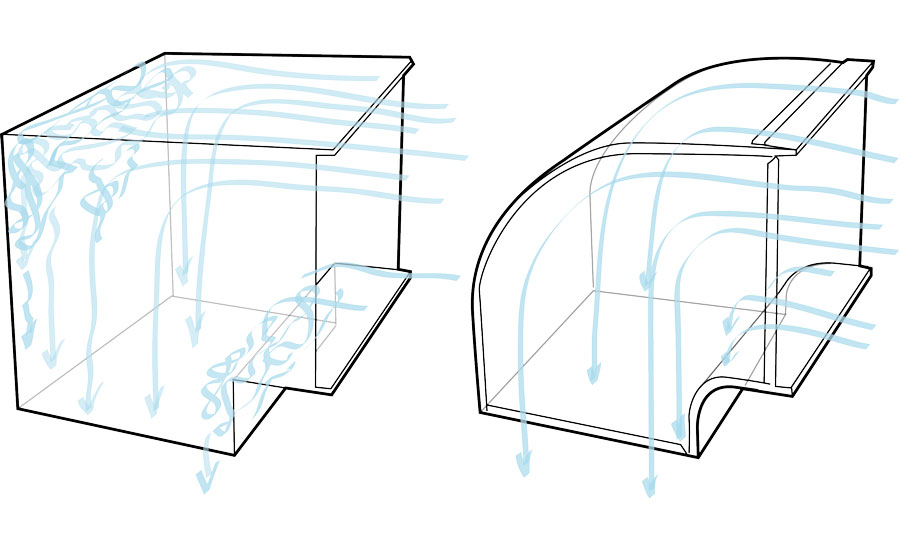

Turbulence drawing from acca s understanding the friction chart. Step one identify the volume of air that will be passing through the duct step two select the duct size from the table that can carry that volume of air step three if desired airflow exceeds the cfm rating increase to the next duct size step four listed cfm is based on typical field results and may vary install dampers step five if duct run exceeds 25 or has excessive. In order to maintain velocity reduce duct size.

Fanno flow is the adiabatic flow through a constant area duct where the effect of friction is considered. The world s leading method for emergency eye irrigation. Always stagger take off ducts by 12 to maintain pressure.

Last take off run to be located 12 18 from end. Compressibility effects often come into consideration although the fanno flow model certainly also applies to incompressible flow for this model the duct area remains constant the flow is assumed to be steady and one dimensional and no mass is added within the duct. It provides thermal and acoustical performance and promotes consistent temperatures for less wasted energy.

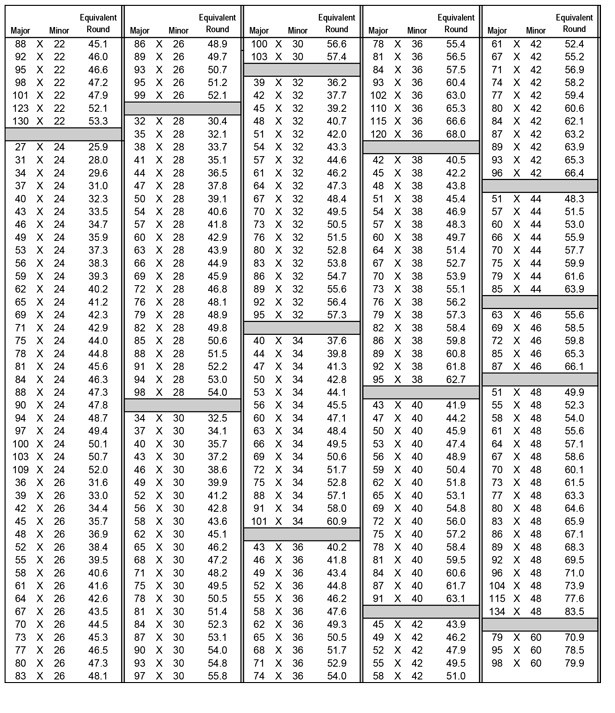

The secret to moving air efficiently through your duct system my article on david hill s 2015 summer camp presentation on oval ducts. Feet of head pressure loss per 100 ft. Flexible duct work must be stretched tightly for maximum air flow.